Sustainability. An environmental friendly product

Our understanding of sustainability

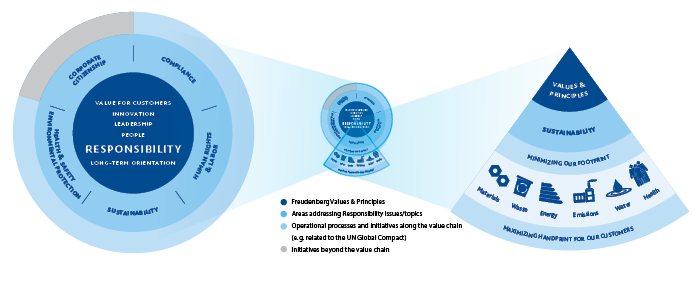

Within Freudenberg group Wettex is oriented towards sustainability and follows the purpose of minimizing the Footprint and maximizing the Handprint for customers and end-users.Footprint means reducing the environmental impact from the company’s manufacturing processes instead Handprint consists in the improved efficiency which derives from customer’s use of Wettex sustainable products.

Innovation constitutes our main advantage as it has a direct positive impact on Footprint and Handprint. The effect on sustainability is considerable.

Wettex is very environmental concerned. As matter of facts it has committed to the projects that we have already mentioned: reducing waste, recycling 100% of the salt and saving energy.

Reduce wasteThe framework of the environmental management system, where efficiency projects are arranged by the Department of Health, Environment and Security, is concretized by a campaign called “Zero Waste” that focuses on minizing waste and utilizing natural resources in a more efficient way. |

We follow up on our waste amounts on a monthly basis and use the key figure of tons of waste per ton of sponge cloth. In recent years, extra efforts, especially regarding cotton handling and reduction of the spillage that occurs at the edges of the sponge roll, have led to a significant reduction in our waste. Viewed over a longer period, the waste has decreased by over 40%.

Recycle 100% of saltWe strive for our use and utilization of raw materials to be as low as possible. The sodium sulfate is used to make Glaubersalt (sodium sulfate and crystal water) by crystallization. It is the crystallized sodium sulfate that creates the voids in the finished fabric. All Glaubersalt is melted out and ends up in sodium sulfate in a saline solution. This salt solution is then again crystallized in the salt factory of FHCS AB. |

|

Save energyTo produce sponge cloth, energy is required in the form of steam, cooling and electrical energy. The energy trend for FHCS AB's production and conversion operations has continuously decreased since 2005. In 2005, the starting point for our energy efficiency work was when we joined the “Energy Efficiency Program in Energy-intensive Industry” program during the Energy Agency's oversight. |

Since 2015, FHCS AB has been conducting its production with green electricity. This means that approximately 45,000 MWh of electrical energy previously purchased from the Nordic market has been replaced by renewable electrical energy from the Swedish electricity market. The focus of the energy efficiency work has been on optimizing machine operations and heat recovery measures. We also focus on purchases: we only buy engines with the highest efficiency. We always look for a better utilization of facilities and a general awareness of the importance of the issue.

Since 2005 we measure our energy efficiency with the key ratio kWh per square meter of sponge cloth (net). We also monitor our carbon dioxide emissions through a service provided by our electricity supplier. As shown in the pictures below, energy efficiency has constantly improved and since the transition to green electricity, carbon dioxide emissions have become close to zero.

Completely microplastic free

Wettex products are completely microplastic free. Microplastics are harmful to people and also contribute to environment deterioration. Especially during last years Wettex has committed to the removal of microplastics from its sponge cloths. But what are microplastics?

They are small plastic pieces less than 5 millimeters long and they usually generate during product manufacturing. Through the food chain humans are ingesting microplastic particles.

Exposure to toxic pollutants could compromise liver function, skin, and nervous system.

Plastic additives like BPA and Phthalates are endocrine-disrupting chemicals (EDC) and they could cause hormonal disease like breast and prostate cancer.

Microplastics are also polluting our environment, especially our waters (ocean, rivers, etc).

Plastics and Microplastics are killing the ocean ecosystem, from fishes to seabirds.

That’s the reason why Wettex put a lot of attention regarding this concern and now we can say that it produces only microplastics free products.

Achievements and goals

Overview of measurement figures and work 2018

The year 2017 was a successful year with many achievements for the organization in its sustainability work. At first 100% salt recycling has been achieved. We have become more energy efficient and we have used fewer resources to produce more sponge cloth.

We work to continuously improve our sustainability work, reduce our footprint and increase our handprint. Our purpose is to continue reducing waste and becoming more energy efficient. By allocating resources for what is central to sustainability work, we have good hopes of achieving our goals.

.